The Portable Particle Counter 3910 – Now Fully Compliant with ISO-14644: 2015

Introduction

When it comes to cleanroom monitoring and verification, compliance with predetermined standards is both essential and ever changing. It can become difficult to keep track of all the adjustments made to these standards, which can cause errors in particle counter readings and render the subsequent calculations useless. Kanomax recognizes this issue and the importance of ensuring accurate measurements that comply completely with current standards. In the interest of both saving time for the technician operating the particle counting instrument and ensuring viable results, Kanomax programs our Portable Particle Counter Model 3910 with the necessary algorithms to automatically read and calculate the particle presence in a given environment. In this case, the standard with which the instruments need to comply is the ISO-14644 standard that was put in place October 29, 2015.

The Standard (ISO-14644)

The previous version of the ISO-14644 was created in 1999, and several major changes have been made since then. In the interest of simplifying the classification process, the 2015 standard removes the need to evaluate the 95% of the upper confidence limit (UCL) for low sample location numbers by adjusting the maximum classification limits. The foremost concern of the life sciences industry is the removal of the ≥ 5µ particle concentration in ISO Class 5. The change represents an improvement in the accuracy of cleanroom contamination evaluation and aseptic process control. Also, in the 1999 version of the standard, the limit was 29 particles per cubic meter. The summary of the benefit of the new method is that, when successfully applied, it assures that at least 90% of the tested room is compliant at a 95% confidence limit.

The Instrument (Portable Particle Counter Model 3910)

With these changes in the standard came changes in the calculations required for the correct data output. With the Kanomax Portable Particle Counter – Model 3910, you can let the instrument be responsible for those calculations, so you can focus less on the equations and more on completing the task at hand. The instrument is calibrated to the specifications dictated by the 21504-1 compliance standard as required by IS14644-2: 2015. Kanomax will also send reminders to the owners of the portable particle counters based on the frequency required by those same standards. Choosing Kanomax for your particle counting instrumentation means all angles are covered.

The Simple Steps

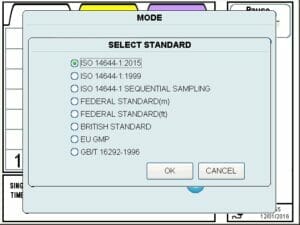

So, how easy is it to measure particle counters based on a chosen standard? You just have to check the box that coincides with the one you need for a given project.

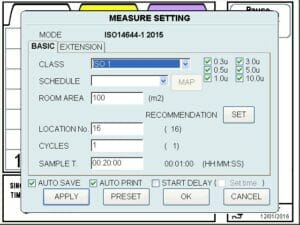

Once the standard is selected and the user is directed to the Measure Setting Window, the Model 3910 shows recommendation based on cleanroom class level and room area. All of the information is displayed in one place instantly, guaranteed to be correct for the standard in question.

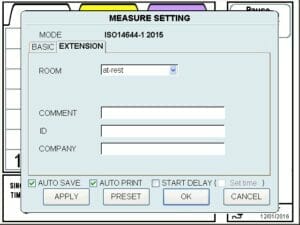

Since all of the number and statistical settings are preprogrammed, the user can then focus on inputting the job details for customizable, accurate record keeping in the Extension tab of the Measure Setting Window.

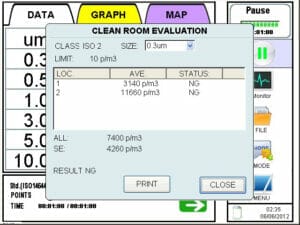

Once the test is complete, the technician can then view the raw data of the results in an organized, easy-to-read table displayed directly on the portable particle counter’s color touchscreen.

The cleanroom evaluation window shows the result (Good or NG) based on cleanroom class level and a specific particle size. The result can be saved and printed out with the built-in printer right at the job site.

Monitoring and verifying cleanrooms based on the most current compliance standards in truly easiest when using a Kanomax portable particle counter, including the Model 3910.