The Model 6162 is a unique anemometer designed for specialized high-temperature testing. Some of the primary applications of a mid-high temperature anemometer include: drying process control, forming process control, exhaust air measurement, and device performance testing (such as industrial ovens). Standards that this instrument apply to include ISO 13579 and NFPA 86.

Drying Process Control: Consists of the removal of water or another liquid via evaporation. In most cases, an air flow applies the heat by convection and then carries away the released water vapor (humidity). The process is often used in food processing industries to dry the product prior to packaging.

Why it’s so important: Improper airflow or heating can result in undesirable outcomes. Some materials will be rendered useless if the drying process is not done precisely. This is true for everything from dehydrated/dried fruits, nuts, meat, ramen, etc., to non-food industries such as film, pharmaceutical applications, and LED panel manufacturing. Even slight variations in food products can render them unsalable or even harmful to consumer health, and can cause warping or other distortion in other products resulting waste due to damage.

Forming Process Control: Like drying, but maintaining a smooth, evenly distributed airflow is critical. Any significant deviations in the air flow or temperature can result in warps, cracks and other imperfections in the finished product. When producing precision products in which imperfections are unacceptable, errors in the forming process will result in significant manufacturing losses.

Why it’s so important: Products such as carbon fiber or polymer based products would not be possible to manufacture without exact control of the forming process. Gathering measurements with that level of accuracy in an environment with extreme temperatures is only possible with an instrument with the ability of the Kanomax Model 6162.

Exhaust Air Measurement: Boilers and incinerators require an exhaust mechanism for the expulsion of the gases released during the combustion or boiling process, and the elevated temperatures in these environments dictate the use of a mid-high temperature anemometer to measure and adjust the output to ensure proper functionality of the exhaust.

Why it’s so important: Monitoring airflow through exhaust ensures that the gases are venting at the rate required to prevent damage to the equipment. It also allows the plant to monitor how much gas their exhaust is expelling day by day. Measuring, and subsequently adjusting these values, allows operators to minimize environmental concerns and/or satisfy environmental regulations. Too much or too little air in the exhaustion process can result in a dirtier burn that produces more waste/pollution. Measuring exhaust air can also save energy and improve the efficiency of the manufacturing process overall.

Device Performance Testing: This type of testing is employed to ensure that all essential implements are functioning at optimal levels. Device performance is often tested in incubators, industrial kilns, re-flow ovens, and other high-temperature environments that require the harmonious interaction of multiple parts and pieces.

Why it’s so important: Aside from aiding the attribution of specific issues to their responsible devices, performance testing is also helpful when determining benchmark levels. These levels can then be used for quality assurance and as an early warning system for malfunctions.

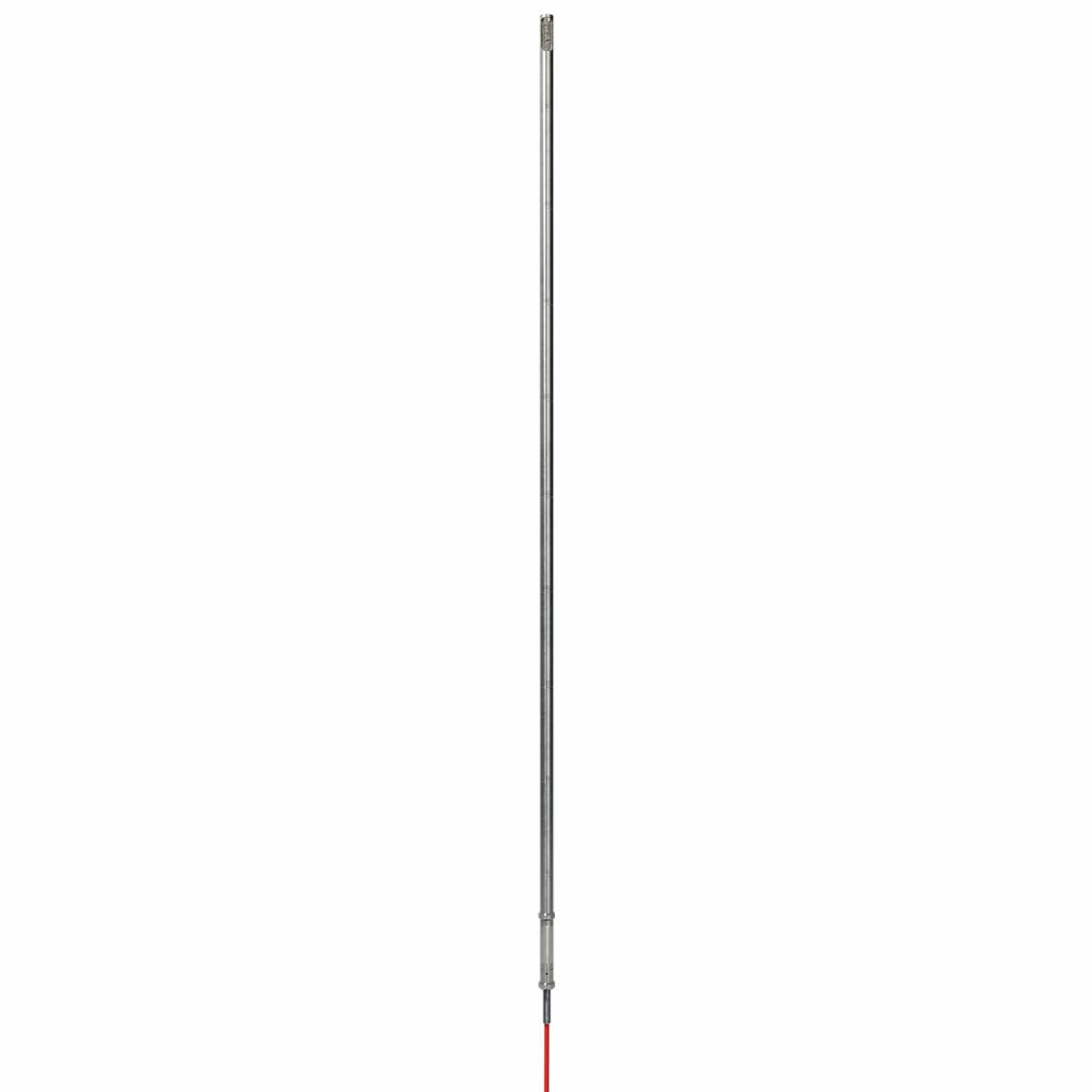

Three interchangeable probes are available for the Model 6162, so you can choose the one that best suits your application. Kanomax also carries optional accessories like extension rods and compression fittings for added convenience.

More Information

Navigate the tab section below to see this product’s Features & Benefits, Specifications, Resources, and more.

- Simultaneous measurement of air velocity and temperature up to 500℃ (932°F)

- Two probes selections, Middle Temperature up to 200℃ (392°F) and High Temperature up to 500℃ (932°F)

- Temperature compensation circuitry ensures accurate velocity measurements in rapidly fluctuating air stream temperatures

- RS232C interface, analog output and remote control terminal equipped

- Store up to 999 measurements

- Simultaneous display of air velocity and temperature

- Secondary temperature compensation circuit provides quick response time

- Standard with a NIST traceable calibration certificate*

- Graphic display allows easy review of historical data

- 6162 allows you to easily interchange smart probes

*NIST TRACEABLE CALIBRATIONS available

- Drying process control

- Forming process control

- Exhaust air measurement

- Device performance testing

- ISO 13579 energy efficiency testing

- NFPA 86 testing for industrial ovens

| Main Unit Specifications | |

|---|---|

| General Specifications | |

| Analog Output | DC 0 to 1V |

| Interface | RS-232C/printer |

| Input | Remote start/stop function |

| Datalogging | Store up to 999 measurements |

| Power Supply | 6 × 1.5 V C cells / AC adapter (100 to 240 V) |

| Operating Environment | |

| Main Unit | 41 – 104 ºF (5 – 40 ºC) |

| Storage Environment | 14 to 122°F (-10 to 50°C) with no condensation |

| Dimensions | |

| Main Unit | 8.7″ x 5.9″ x 3.3″ (220 x 150 x 85mm) |

| Weight | 3.9 lbs (1.8kg) |

| What’s Included | Meter, operation manual, AC adapter, analog output cable (2pc), shoulder strap, C-batteries (6 qty) |

| Warranty | 1 year |

| Probe Specifications | |||

|---|---|---|---|

| Model | 0203 | 0204 | |

| Temperature Range | |||

| Air Velocity Measuring Range | 32 to 212°F | 40 to 9840 fpm (0.2 to 50.0 m/s) | |

| 212 to 392°F | 80 to 9840 fpm (0.4 to 50.0 m/s) | ||

| 392 to 572°F | n/a | 138 to 9840 fpm (0.7 to 50.0 m/s) | |

| 572 to 752°F | n/a | 197 to 9840 fpm (1.0 to 50.0 m/s) | |

| Accuracy | +/- 3% of reading | ||

| Temperature Measuring Range | 32 to 392°F (0 to 200°C) | 32 to 932°F (0 to 500°C) | |

| Accuracy | +/- 1% of reading | ||

| General Specifications | |||

| Dimensions / Weight | Ø 11 x 200mm (Ø 0.4″ x 7.8″), 0.4 lbs (200 g) | Ø 14 x 1000mm (Ø 0.6″ x 39.4″)1.1 lbs (500 g) | |

| Probe Cables | Teflon Coating | ||

| Heat-resistance | 392°F (200°C) | ||

| Extension Cable | Vinyl Coating | ||

| Heat-resistance | 176°F (80°C) | ||

User Manual

Data Sheet - English

Data Sheet - Espanol

Application Note

Application Note - Anemometer Selection Guide

Engineering Drawings - Probe Dimensions

Software - Manual

- Mid-Temp Probe: Model 0203

- High-Temp Probe: Model 0204

- High-Temp Probe: Model 0205

- Extension Rod for High-Temp Probe (0204)

- Extension Rod for Mid-Temp Probe (0203)

- Compression Fitting for 0203: Model 6162-07

- Compression Fitting for 0204/0205: Model 6162-06

- RS232C Cable: Model 6162-05

- Portable Printer Cable: Model 6511-09

- Portable Printer: Model DPU-S245

- Portable Printer Paper: Model TP-5RLPK

- PC Software: Model 6000-41

Getting Started with the Kanomax HTA 6162 Series

Getting Started with the High Temperature Anemometer 6162 Series

Kanomax High Temperature Anemometers are unique airflow testing instruments designed for very hot environments and applications, including industrial oven testing and lumber kiln drying process.

Learn about 6162 Series anemometers in the video below.

Our sales representatives are here to help you find the right instrument for your application. Fast.

Request a quote today to find the product you need with expert assistance.