Semiconductor Manufacturing

Expert solutions for semiconductor manufacturing

Due to unprecedented demand and unforeseen shortages in the industry, highly efficient and high quality semiconductor manufacturing practices are incredibly important. Extremely accurate and reliable airborne particle counters are essential, and Kanomax handheld, portable, and nano particle counters are the best available for fulfilling that purpose.

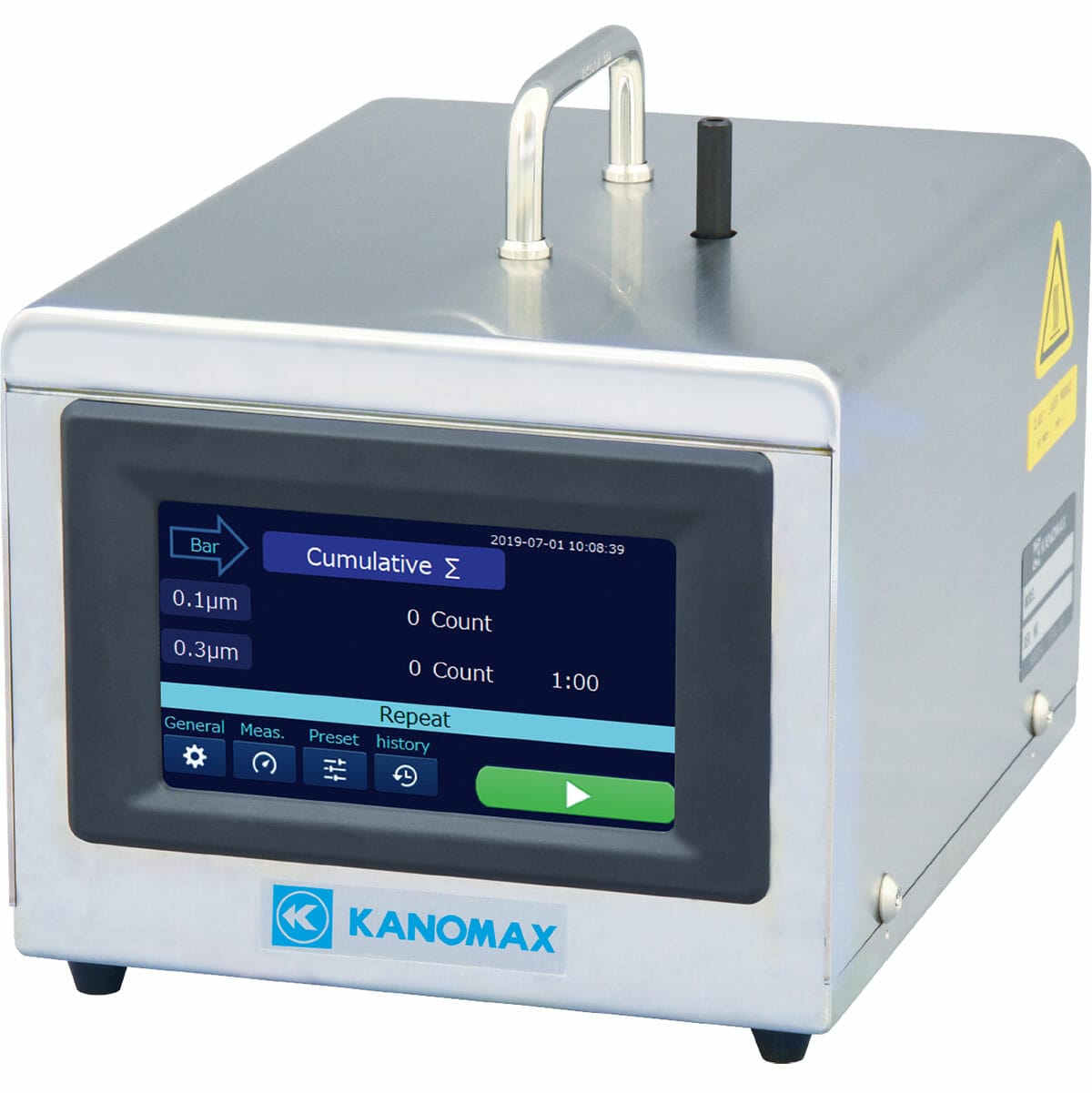

Kanomax USA offers its brand new 0.1 µm Portable Particle Counter, essential in semiconductor manufacturing, as well as Handheld Particle Counters and Portable Particle Counters that can measure 0.3 µm, 0.5 µm, 1.0 µm, 3.0 µm, 5.0µm, and 10.0µm (respective of model). These units can accommodate particle spot-checking and monitoring in cleanroom manufacturing environments, and can even be integrated into existing manufacturing equipment, such as in the case of the 0.1 µm Portable Particle Counter – Model 3950. These models all feature:

- Store up to 10,000 measurements

- Compact and Light weight

- Remote control software

- Easy to read and interpret data due to large screen with full color and graphic display

- Compliant with current ISO-14644 standard

- Compliant with current ISO 21501-4 standard

- Grants the ability to control and monitor the instrument remotely through a PC

- Easy data transfer to USB drive

Kanomax USA’s sister company, Kanomax FMT offers nanoparticle counters, such as their Handheld Condensation Particle Counter (CPC) – Model 3800. This class of water-based particle counter features:

- .015 micron (15ηm) minimum sensitivity

- Stores up to 10000 measurements

- PC Interface with USB & Software for real-time measurements while displaying time fluctuation graph