Cleanroom Monitoring

Cleanroom monitoring for meeting the highest environmental standards

A cleanroom can be defined as a strictly controlled environment of the purest kind. During the technology boom, the semiconductor and HDD industries were the biggest users of cleanrooms and in a stable way, they still remain one of the most important users. However, as the world of science rapidly progresses, the demand for cleanrooms from players especially in the bio-tech and pharmaceutical markets have become noticeably strong. As a result cleanroom monitoring systems have become essential.

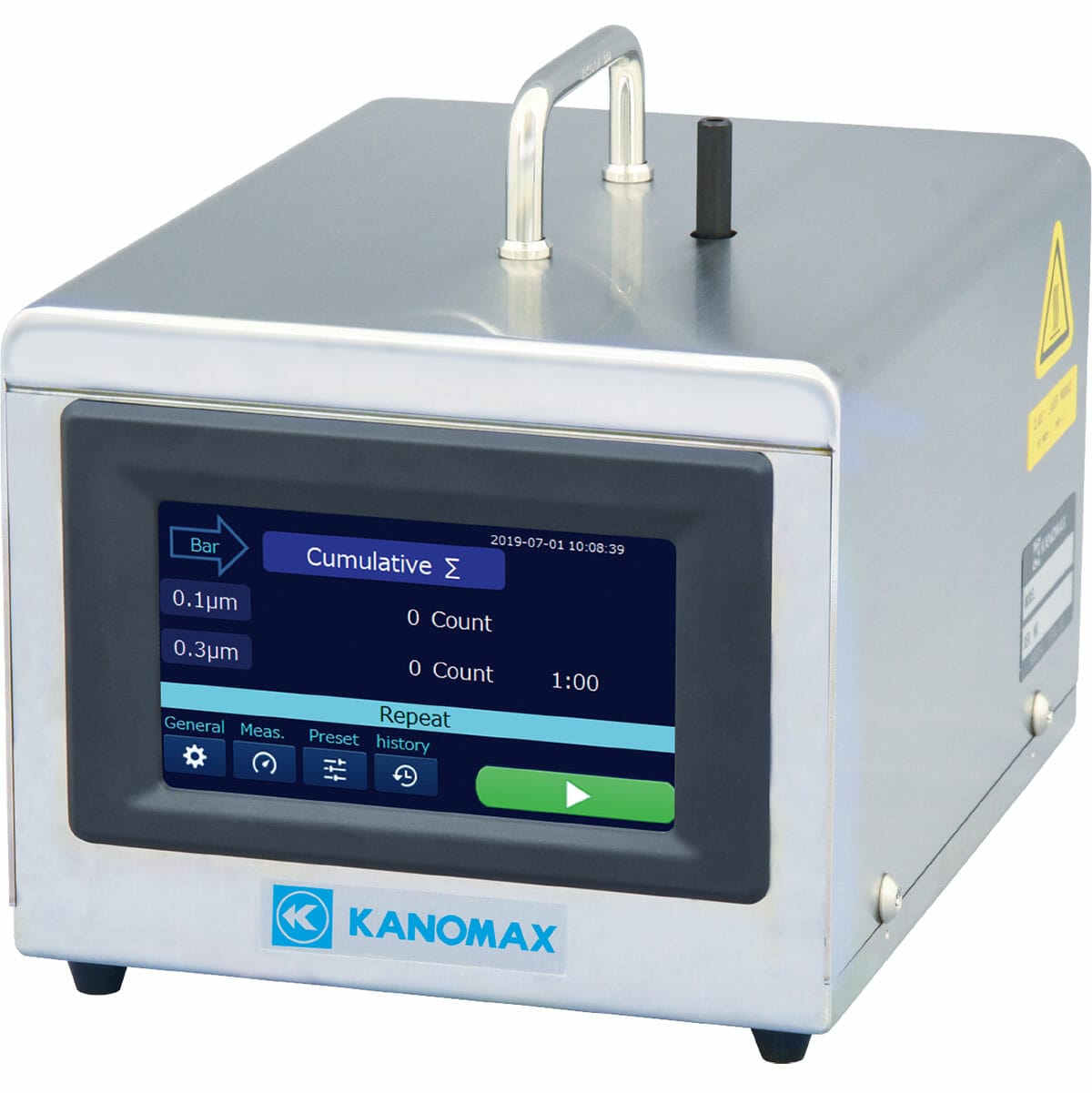

The cleanroom class level of bio-techs and pharmaceuticals (typically around Class 5) is still less stringent than those of semiconductor cleanrooms (an extreme and rare example is a Subclass 0.1 cleanroom at the semiconductor R&D level). Nonetheless, very few precision measurement manufacturers fulfill the cleanroom monitoring instrumentation needs for such environments. Kanomax products provides best-in-class instruments for these controlled environment monitoring and measurement needs.

Kanomax provides the very best in particle counting solutions, including our: Handheld Particle Counters, Portable Particle Counters, Remote Particle Sensors w/ Analog Output, Aerosol Particle Monitor and complete Cleanroom Monitoring Systems (CRMS).