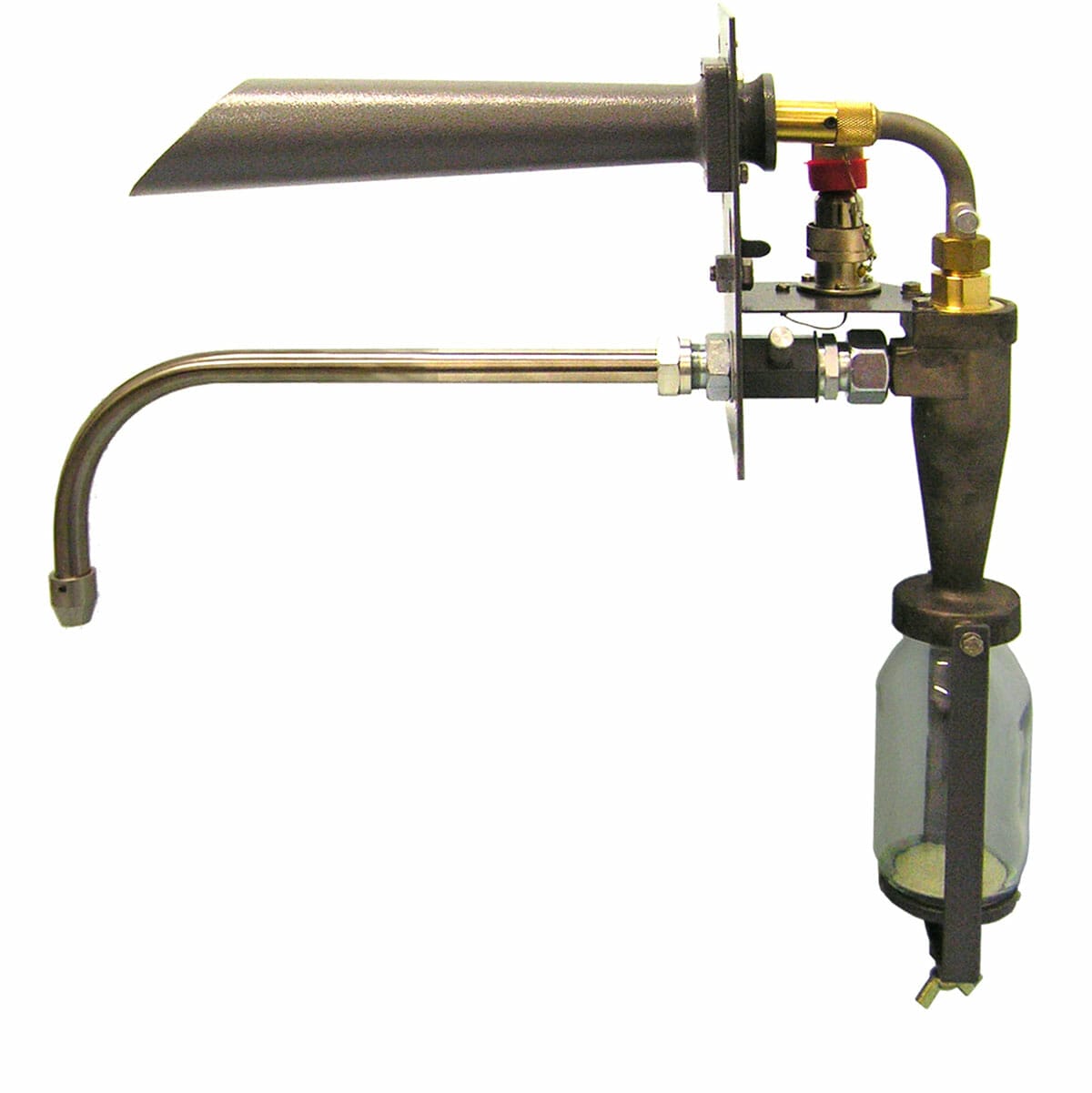

The Kanomax Digital Dust Monitor – Model 3443 measures aerosol concentrations corresponding to PM10. The intake isolates the aerosol sample so that the optics chamber is kept sterile for improved reliability and low maintenance. The unit measures 0.1 to 10µm particle size aerosol contaminants such as fumes, dust, smoke and mists. It is battery-operated, data-logging, light-scattering laser photometer that gives you real time aerosol mass readings. It is also suitable for clean office settings well as harsh industrial workplaces, construction and environmental sites, and outdoor applications.

More Information

Navigate the tab section below to see this product’s Features & Benefits, Specifications, Resources, and more.

- Measures PM 10 particle matters, such as dust, fumes, and smoke

- Real time and long term measurements of dust concentration

- Compact and lightweight unit

- PC interface with USB and software for downloading data to your PC

- Analog output controls other devices

- Data logging up to 100,000 measurements and displays MIN / MAX / AVG and Timing graph for review

- Complete with rubber protector, shoulder strap, data processing software, USB cable, AC adaptor, 2 pcs LCD protective sheet, rubber cap, 2 pcs filter

- Calibration certificate

- Measures aerosol concentrations corresponding to PM10.

- The intake isolates the aerosol sample so that the optics chamber is kept sterile for improved reliability and low maintenance.

- This measures 0.1 to 10µm particle size aerosol contaminants such as fumes, dust, smoke and mists.

- Battery-operated, data-logging, light-scattering laser photometer that gives you real time aerosol mass readings.

- Suitable for clean office settings well as harsh industrial workplaces, construction and environmental sites, and outdoor applications.

- IAQ Investigations

- Industrial Hygiene

- Occupational Health & Safety

- Contamination Exposure Monitoring

- Manufacturing Process Control

| Main Unit Specifications | |

|---|---|

| Measuring Method | Light Scattering Method |

| Measuring Object | Airborne Particle Matter 0.1 to 10 µm |

| Measuring Range | 0.001 to 10.0 mg/m3 |

| Accuracy | +/- 10% of reading |

| General Specifications | |

| Light Source | Laser diode |

| Data Logging | 100,000 data and time stamped measurements |

| Interface | USB |

| Output | 0 to 1 V, Pulse, Alarm |

| Power Supply | 6 AA batteries or AC adapter |

| Dimensions | W 6.4″ x H 4.3″ x D 2.4″ (162 x 109 x 60mm) |

| Weight | 2.9 lbs. (1.3 kg) |

| Warranty | 1 year |

| What’s Included | Meter, Operation manual, Data processing software, USB cable, AC adapter, Rubber protector, LCD protective sheet, Shoulder strap, Filter, NIST TRACEABLE CALIBRATION certificate |

User Manual

Data Sheet - English

Data Sheet - Espanol

Application Note - Dust Monitor Guide

Software Manual

- Digital Dust Monitor Spare Rubber Protector: Model 3442-02

- Digital Dust Monitor Spare Rubber Cap: Model 3442-10

- Digital Dust Monitor Filter: Model 3431-03

- LCD Protective Sheet: Model 3442-04

- Carrying Case for Dust Monitor: Model 3442-05

- Digital Dust Monitor Analog Cable: Model 3442-01

- Tripod: Model TRIPOD-01

Our sales representatives are here to help you find the right instrument for your application. Fast.

Request a quote today to find the product you need with expert assistance.